Fixing the Future: How Digital Twins Will Transform Project Management

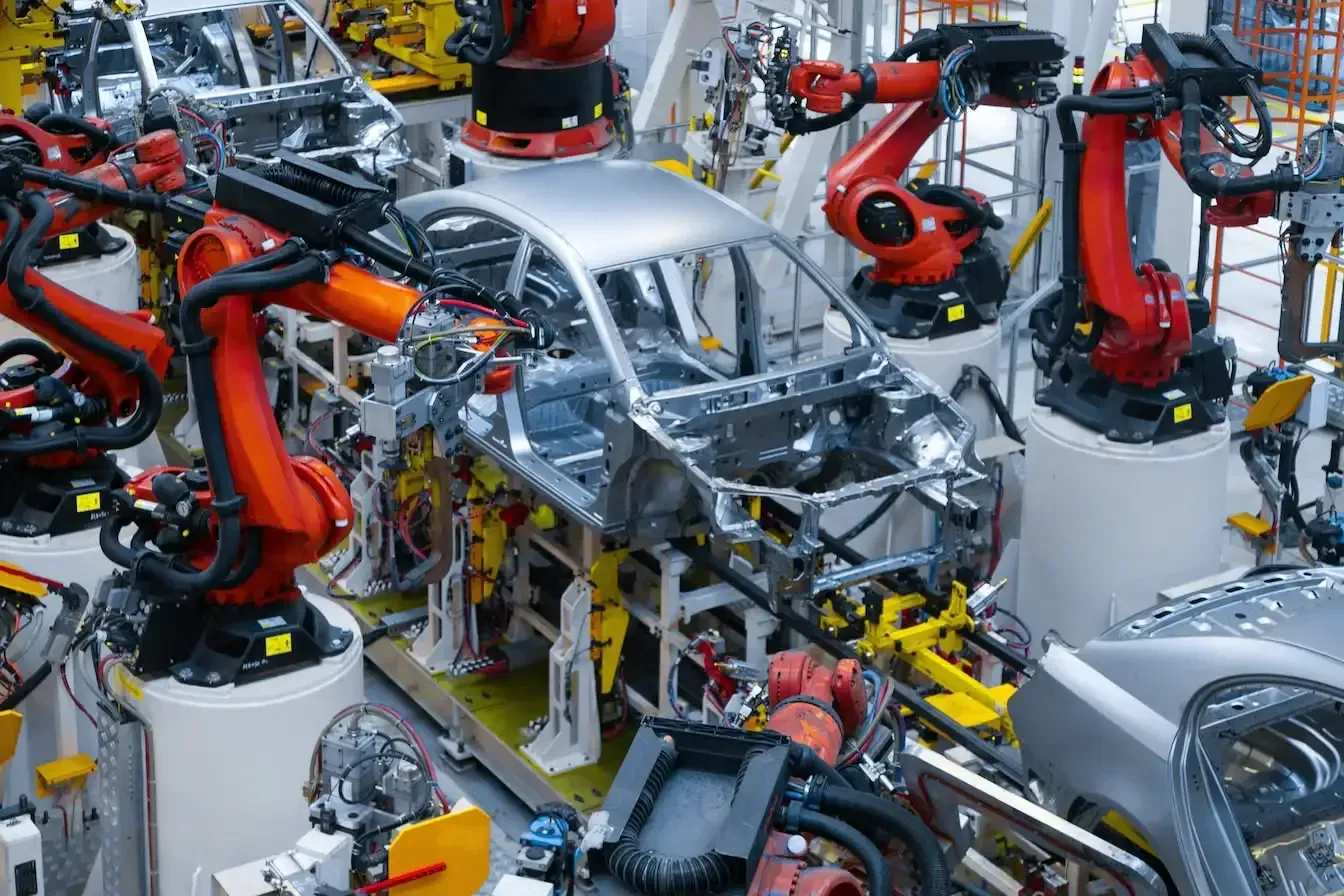

Standing on the factory floor at BMW's Munich plant you hear the precise stop-start movement of twirling robotic arms. Workers move alongside in careful human-machine collaboration. But what's truly remarkable isn't visible to the naked eye. Every movement, every process, every potential failure has already been rehearsed countless times in a parallel digital universe — a virtual twin that exists purely in code yet mirrors the physical world with uncanny accuracy.

A car assembly line with multiple robotic arms and track. Source: Unsplash+.

This is a new frontier for project management, where the ancient art of planning meets the cutting-edge science of simulation. Digital twins — virtual replicas of physical systems that update in real-time — are transforming how we conceive, execute, and optimise complex projects across industries. What began as a niche technology in manufacturing has evolved into a $25 billion market that's reshaping the fundamental nature of project execution[1].

"Everything we are producing here in Munich has already been planned virtually," explains Peter Weber, BMW's plant director.

"You can really have a run-through and improve it wherever necessary"[2].

This isn't just about efficiency — it's about reimagining the very nature of project management itself.

The Digital Twin Revolution in Project Management

The traditional project management paradigm operates on educated guesswork, historical data, and the hope that Murphy's Law won't strike at the worst possible moment. Digital twins flip this model on its head, creating what industry experts call ‘decision superiority’ — the ability to test scenarios, predict outcomes, and optimise performance before committing resources to the physical world[3].

So, how established is this new frontier? According to recent research,

92% of companies implementing digital twin technology report returns exceeding 10%, with half achieving returns above 20%[4]. More striking still is the breadth of adoption:

75% of enterprises surveyed had implemented digital twin solutions by 2023, up from just 20% in 2020[1].

This isn't just a new way to visualise projects or run simulations — it's about a fundamental shift in how project teams operate alongside technology. Digital twins serve as a bridge between the abstract world of project planning and the concrete reality of execution, allowing managers to predict issues before they occur and test solutions in a risk-free environment.

This creates a new paradigm that can be applied across a range of industries and sector-specific solutions.

Sector-Specific Applications

The versatility of digital twin technology becomes apparent when examining its implementation across diverse industries:

- Manufacturing: BMW's Virtual Factory processes over 40 vehicle models virtually before production, reducing planning costs by 30% and enabling 20% productivity improvements in new facilities[5][2]

- Healthcare: Patient-specific digital twins enable personalised treatment plans, with hospitals using virtual models to optimise resource allocation and predict equipment maintenance needs[6][7]

- Construction: Highway projects employ digital twins for real-time safety monitoring and progress tracking, reducing rework by 40% and cutting carbon emissions by 30%[8][9]

- Energy: Rolls-Royce's engine digital twins predict maintenance needs across global fleets, enabling proactive interventions that prevent costly failures and optimise fuel efficiency[10][11]

- Smart Cities: Urban planners use digital twins to simulate traffic patterns, optimise energy consumption, and prepare for emergency scenarios, with some implementations reducing carbon emissions by 21,000 tonnes annually[12][13]

- Ports and Maritime: Container terminal operations leverage digital twins for logistics optimisation, while maritime fleets use virtual models to enhance safety and operational efficiency[14]

The Value Proposition: Beyond Efficiency

The benefits of digital twins extend far beyond traditional metrics of project success. They represent a fundamental

move from reactive to proactive management, from crisis response to crisis prevention.

The efficiency gains are measurable and substantial. In construction, digital twins have demonstrated the ability to eliminate low efficiency and productivity challenges that have plagued the industry for decades[16].

But the true value lies in the transformation of decision-making itself. Digital twins provide what researchers call

‘comprehensive project views,’ enabling managers to understand complex interdependencies and optimise resource allocation with unprecedented precision[17]. This translates to better stakeholder communication, enhanced collaboration, and more effective risk management.

Implementation Barriers: The Reality Check

Despite the compelling benefits, digital twin implementation faces significant challenges that project managers must approach carefully. The complexity of building and maintaining these systems can be overwhelming, particularly for organisations lacking advanced computational resources.

Data quality emerges as the primary obstacle, with 43% of professionals identifying it as the biggest implementation challenge[17]. The integration of multiple data sources — from IoT sensors to legacy systems — requires careful orchestration and often reveals gaps in existing data infrastructure.

Non-technical barriers prove equally challenging. A survey of 61 industrial professionals found that issues like lack of expertise and specialists are more likely to cause implementation difficulties than technical problems[19]. The rapid pace of technological change requires continuous skill development, while managing cybersecurity risks has become a critical concern as digital twins become integral to critical infrastructure[20].

Organisational resistance represents another significant hurdle. The transformation requires not just new technology but new ways of thinking about project execution. As one expert notes,

"A big mistake companies make is allowing their desire for perfect to get in the way of good enough"[18]. Successful implementations require cultural change,

facilitated by change management, alongside technological adoption.

Lastly, cost considerations cannot be ignored. While 92% of tracked implementations show ROI exceeding 10%, the initial investment in infrastructure, training, and system integration can be substantial[4]. Companies must carefully balance the promise of future returns against immediate resource constraints.

The Future of Project Management: AI-Enhanced Twins

The convergence of digital twins and artificial intelligence (including Agentic AI) represents the next leap forward in project management. Generative AI is already accelerating digital twin development, reducing implementation timelines from months to weeks[21]. This integration promises to make digital twins more intuitive, more predictive, and more valuable to project teams.

The emerging industrial metaverse, built on platforms like NVIDIA Omniverse, is creating immersive environments where project teams can collaborate in virtual spaces that mirror physical reality[5]. These developments point toward a future where the distinction between digital and physical project management becomes increasingly blurred.

Looking far ahead, digital twins will likely become an

industry-standard. As university courses and apprenticeships widen the resource pool — and as AI agents carry weight off the learning curve — the technology will open up to smaller businesses and a broader range of industries.

The question for project leaders right now is when to act. Once that decision is made, it becomes a question of how quickly they can hire and train teams to leverage this technology effectively.

Conclusion: The New Project Management Horizon

Digital twins offer project managers something that has long been considered impossible: the ability to predict the future before it happens, to test solutions before committing resources, and to optimise performance in ways previously unimaginable.

If the metaverse ends up being many things at once — including a testing ground for new projects, products and solutions — project management will have untold abilities to

take the right path first time: saving money, time and potentially lives.

How We Can Help

At Cambridge Management Consulting, our Project Management services — led by industry expert Jason Jennings — help organisations deliver programmes smarter, faster, and with less risk. Whether you’re exploring the potential of Digital Twins or seeking to optimise complex programmes, our team brings the clarity and execution you need to ensure project success.

Learn more at

www.cambridgemc.com/project-management or get in touch using the form below.

References

1. https://hexagon.com/resources/insights/digital-twin/statistics

2. https://www.automotivemanufacturingsolutions.com/smart-factory/future-ready-bmws-digital-transformation-of-its-munich-plant-and-beyond/523748

3. https://www.youtube.com/watch?v=ZZWj9k9_e98

4. https://www.visualcapitalist.com/dp/charted-the-return-on-investment-of-digital-twins/

5. https://www.processexcellencenetwork.com/digital-transformation/news/bmw-group-transforms-global-manufacturing-operations-with-advanced-digital-twin-technology

6. https://pmc.ncbi.nlm.nih.gov/articles/PMC10513171/

7. https://www.frontiersin.org/journals/digital-health/articles/10.3389/fdgth.2023.1253050/full

8. https://www.mdpi.com/2075-5309/14/7/2216

9. https://dchub.me/digital-construction/construction/journeys-in-digital-twin-implementation-real-world-success-stories/

10. https://www.youtube.com/watch?v=l2Kh5rgN2HY

11. https://www.thenakedscientists.com/articles/interviews/rolls-royces-digital-twin-engines

12. https://www.govtech.com/smart-cities/digital-twin-technology-can-make-smart-cities-even-smarter.html

13. https://www.forbes.com/sites/delltechnologies/2024/06/26/urban-digital-twins-ai-comes-to-city-planning/

14. https://www.workshopitpm.kyiv.ua/itpm-2024-supply-chain-management-information-system-project-with-the-use-of-digital-twins/

15. https://www.mdpi.com/2076-3417/14/11/4787

16. https://www.emerald.com/insight/content/doi/10.1108/SASBE-03-2024-0082/full/html

17. https://ieeexplore.ieee.org/document/10806680/

18. https://jpt.spe.org/digital-twins-7-challenges-how-to-navigate-them

19. https://asmedigitalcollection.asme.org/IDETC-CIE/proceedings-abstract/IDETC-CIE2022/86212/V002T02A055/1150306

20. https://cionews.co.in/revolutionizing-industries-the-future-of-digital-twin-technology-beyond-2024/

21. https://www.zdnet.com/article/6-digital-twin-building-blocks-businesses-need-and-how-ai-fits-in/

22. https://futuredigitaltwin.com/events/fdt-usa-2025/quotes/

Contact - Digital Twins Blog

Subscribe to our Newsletter

Blog Subscribe

SHARE CONTENT